Mechanical power transmission is transferring the mechanical work produced in machines from one part to another or from a power source (an engine or motor) to the actual workpiece. The different applications, speed requirements, load characteristics, and efficiency in mechanical systems dictate the use of several power transmission, such as belt drives, chain drives, rope drives, and gear drives.

- Introduction to Power Transmission

Mechanical power transmission methods usually involve a machine-driven device converting rotational motion and torque from a source (engine, motor, etc.) to drive elements like wheels, pulleys, conveyors, etc. Diverse transmission systems are devised for a variety of power ratings, environmental conditions, and speed characteristics.

-

-

- Belt Drives: Move belts between the pulleys to trade power. Mainly used in scenarios where the power and speed are somewhat restrained.

- Chain Drives: Are employed in handling tasks that require the transfer of power through high torque capacity and are known for their durability. Generally, these are the drives that support high load operations.

- Rope Drives: Like belt drives only here, ropes are used to transmit power. They are usually used to achieve high-speed ratios and the distance between the driver and the driven pulleys is long.

- Gear Drives: Gears are utilized as the transportation medium to obtain the exact speed ratio required without much energy loss. Frequently, this method is a suggestion for those systems in need of speed control and torque transmission.

-

- Belt Drives

Belt drives use belts that are as flexible as possible to gain the power from two shafts that are in rotation. The belt is wrapped around the pulleys and spins due to the friction between the belt and the pulleys.

Types of Belt Drives:

-

-

- Light Belt Drive: Use in low-power applications, most commonly small devices or light load situations. For example, one of the elements of the garage or home appliances.

- Medium Belt Drive: Use in medium load applications, that is, where there is a power of transmission of a not so great amount. For example, industrial fans, blowers, and so on.

- Heavy Belt Drive: Used in heavy machines where large amounts of power are being transmitted. Examples are the use of conveyor systems in factories and large industrial machines.

-

Types of Belts:

-

-

- Flat Belts: These belts are flat and wide and they are generally used for low to intermediate power transmission. They are applied in the systems where the length of the pulleys is short.

- Example: The belt, which is connecting a motor to a fan, is an example.

- V-Belts: The trapezoidal cross-section provides for these belts a more sufficient frictional surface, which is good for moderate to high-power transmission. The flight belts are why efficient have lower space than the flight belts in smaller space.

- Example: The engine and HVAC systems in an automotive vehicle make use of V-belts.

- «Circular Belts: These are round cross-section belts and are less common than flat and V-belts. They are used in low power applications.

- Example: Small household machines and some conveyor belts.

- Flat Belts: These belts are flat and wide and they are generally used for low to intermediate power transmission. They are applied in the systems where the length of the pulleys is short.

-

Differences Between Open and Cross Belt Drives:

-

-

- Open Belt Drive: Both pulleys turn in the same direction. This unit is simpler and is normally used when the belts are aligned on the same plane.

- Cross Belt Drive: In this case, the pulleys are in opposite directions. The belt cross on itself, which makes it more compact and is applied when the space is limited or specific directions of rotation are required.

-

- Chain Drives

Chain drives make use of a roller chain and sprockets to transfer power. Chains are suitable for high-speed operation and can transmit a large amount of torque.

Types of Chains Used:

-

-

- Roller Chains: The most common chain used in a set of links that roll over sprockets. It is used in both light and heavy applications.

- Block Chains: Usually employed in the heavy-duty application in which the shock loads cannot be endured by roller chains.

- Silent Chains: The chains are built especially to allow a more tranquil operation and are often used in automotive applications.

-

Advantages of Chain Drives:

-

-

- The high transmission capacity.

- The power is transmitted exactly and directly, so there is no slipping at all.

- It is possible to use chain drives over longer distances in comparison to belt drives.

- Belts are not as long-lasting as chains, especially in difficult conditions.

-

Disadvantages of Chain Drives:

-

-

- Lubrication is required to prevent the wearing of parts.

- Noise and vibration can be below those of belt drives.

- Maintenance is more complicated, and timely check of the tension is mandatory.

-

Example: A chain drive is a system in a bicycle where the motor (pedal power) moves the rear wheel.

- Rope Drives

A rope drive is the use of flexible ropes made of steel or synthetic materials to transfer power between pulleys. It is also possible that the rope’s flexibility and strength are the reason for smooth power transfer even at higher speeds.

Types of Ropes Used:

-

-

- Steel Ropes: These are the ropes, commonly used for heavy-duty applications, such as hoists and cranes.

- Synthetic Ropes: They are the ropes lighter and more flexible than steel ropes, usually used in machinery where a lightweight or low friction is important.

-

Advantages of Rope Drives:

-

-

- It is possible to use it for transferring power to far distances.

- These can be less noisy than chain drives.

- It can bear heavy loads and perform at high speeds more smoothly.

-

Disadvantages of Rope Drives:

-

-

- It may start losing its length over time, so it is necessary to make tensions at regular intervals.

- Moreover, it can be worn out due to extreme weather conditions (e.g., moisture or abrasive materials).

- On the other hand, it demands more precise alignment to avoid the slipping or wearing.

-

Example: Top-rope drives are generally found inside the large industrial machinery or systems requiring a serious power transfer over long distances, say the ski lifts or those cranes normally used.

- Gear Drives

Gear drives the series of gears that transmit power and energy. The gears act as efficient and accurate means of power transmission, especially in instances where precise speed ratios are demanded.

Types of Gear Drives:

-

-

- Spur Gears: These are the most commonly employed type of mechanical power transmission with gear-teeth that are in the same line with the axis of the shaft. It is the kind that uses for mechanical power transmission.

- An Example: Using gears in cars and machines.

- Helical Gears: Gears that have teeth inclined at an angle. They provide a quieter and smoother motion compared to spur gears.

- An Example: Gearboxes in industrial machinery.

- Bevel Gears: Gears where the axis of the shafts intersects, mainly used for transmission at right angles.

- An Example: Unique gears in cars.

- Worm Gears: Gears that have a screw-shaped gear wheel that meshes with a toothed wheel, usually, this is the gear that is used for the first stage reduction of the main gear.

- An Example: Winch systems or gearboxes in heavy machinery.

- Spur Gears: These are the most commonly employed type of mechanical power transmission with gear-teeth that are in the same line with the axis of the shaft. It is the kind that uses for mechanical power transmission.

-

Benefits of Gear Drives:

-

-

- High efficiency (95% or higher).

- It’s easy to maintain the specified speed ratios.

- High stress and torque can be withstood by it.

- They are long-lived and they do not require much maintenance.

-

Pitfalls of Gear Drives:

-

-

- Comparatively, they are more expensive than the belt or chain drives.

- Complexity involved in the design and manufacturing of the parts/code.

- Noise production and requiring periodic lubrication are also possible.

-

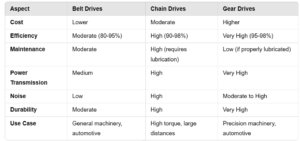

Comparison of Belt, Chain, and Gear Drives:

Example of Gear Drive Application: In a gear-driven conveyor belt system where high precision and torque are necessary, gear drives ensure the same speed is maintained without any slipping, thus, they are the best for the industrial purposes application.